The facilities at Dursley are complemented by our own in-house metal treatment service, from electrostatic paint spraying to de-greasing & anodising for Aerospace & harsh environment sectors.

These facilities have recently been significantly expanded by the investment of a large scale Tartaric Sulphuric Anodising plant which meets the exacting demands of large aerospace OEM customers.

Quality Assurance

TJW have recently invested in a new larger TSA (Tartaric Sulphuric Anodise) plant processing to AIPS02-01-003 to further support Airbus. This process replaces our current CAA activity that TJW has successfully offered over the past 20 years.

This additional capability is the result of our continued efforts to support Airbus and their sub tier suppliers in their policy to phase out the use of Chromates from their product / supply chain.

Our New anodising envelope for the new plant is 850 x 300 x 1300mm.

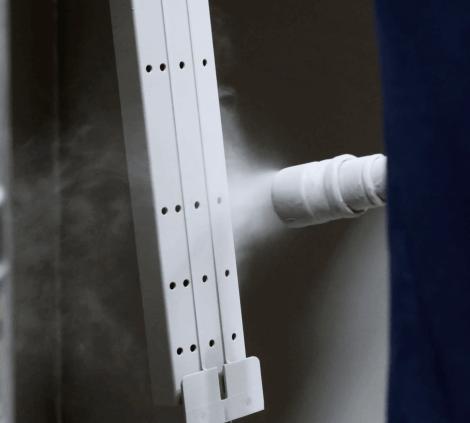

Electrostatic paint spray capability provides a variety of finishes following anodising.

Slow bake electric oven facilities provide hardened cure finishes as follows: